- Introduction: The Growing Demand for Custom Sunglasses

- Why Work with a Professional Custom Sunglasses Manufacturer?

- The Custom Sunglasses Manufacturing Process

- 3.1 Design & Concept Development

- 3.2 Material Selection

- 3.3 Prototyping & Sampling

- 3.4 Mass Production

- 3.5 Quality Control & Certifications

- Customization Options at Joysee Eyewear

- 4.1 Frame Styles & Materials

- 4.2 Lens Technologies & Coatings

- 4.3 Branding & Logo Printing

- Why Choose Joysee Eyewear as Your Custom Sunglasses Manufacturer?

- 5.1 10+ Years of Manufacturing Expertise

- 5.2 State-of-the-Art Production Facilities

- 5.3 Eco-Friendly & Sustainable Manufacturing

- 5.4 Global Shipping & Fast Lead Times

- Case Studies: Success Stories from Our Clients

- Future Trends in the Custom Sunglasses Industry

- Conclusion: How to Start Your Custom Sunglasses Project with Joysee Eyewear

1. Introduction: The Growing Demand for Custom Sunglasses

With the rise of personalized fashion and brand identity, more companies are seeking custom sunglasses manufacturers to create unique eyewear collections. Whether you’re a fashion brand, sports retailer, or promotional company, offering personalized sunglasses can boost brand recognition and customer engagement.

As a leading custom sunglasses supplier, Joysee Eyewear specializes in transforming creative concepts into high-quality, custom-made sunglasses.

2. Why Work with a Professional Custom Sunglasses Manufacturer?

Choosing a professional sunglasses manufacturer ensures:

✅ Superior Quality & Durability – High-end materials & advanced production techniques

✅ Full Customization – Frame styles, lens coatings, branding, packaging

✅ Cost-Effective Production – Scalable solutions for bulk orders

✅ Faster Time-to-Market – Efficient supply chain & streamlined manufacturing

With Joysee Eyewear, brands gain a reliable manufacturing partner that ensures top-tier craftsmanship and hassle-free production.

3. The Custom Sunglasses Manufacturing Process

3.1 Design & Concept Development

- Every custom eyewear project starts with a unique design concept.

- Our designers use 3D modeling & CAD software to refine the frame structure.

- Clients provide brand guidelines, color preferences, and logo requirements.

3.2 Material Selection

Choosing the right frame and lens materials is crucial for comfort and durability:

- Frame Materials: Acetate, TR90, stainless steel, titanium, recycled materials

- Lens Options: Polarized, anti-blue light, mirrored, gradient, UV400 protection

3.3 Prototyping & Sampling

- A prototype is created to test comfort, fit, and overall aesthetic appeal.

- Clients receive physical samples before moving to mass production.

3.4 Mass Production

Once approved, production begins:

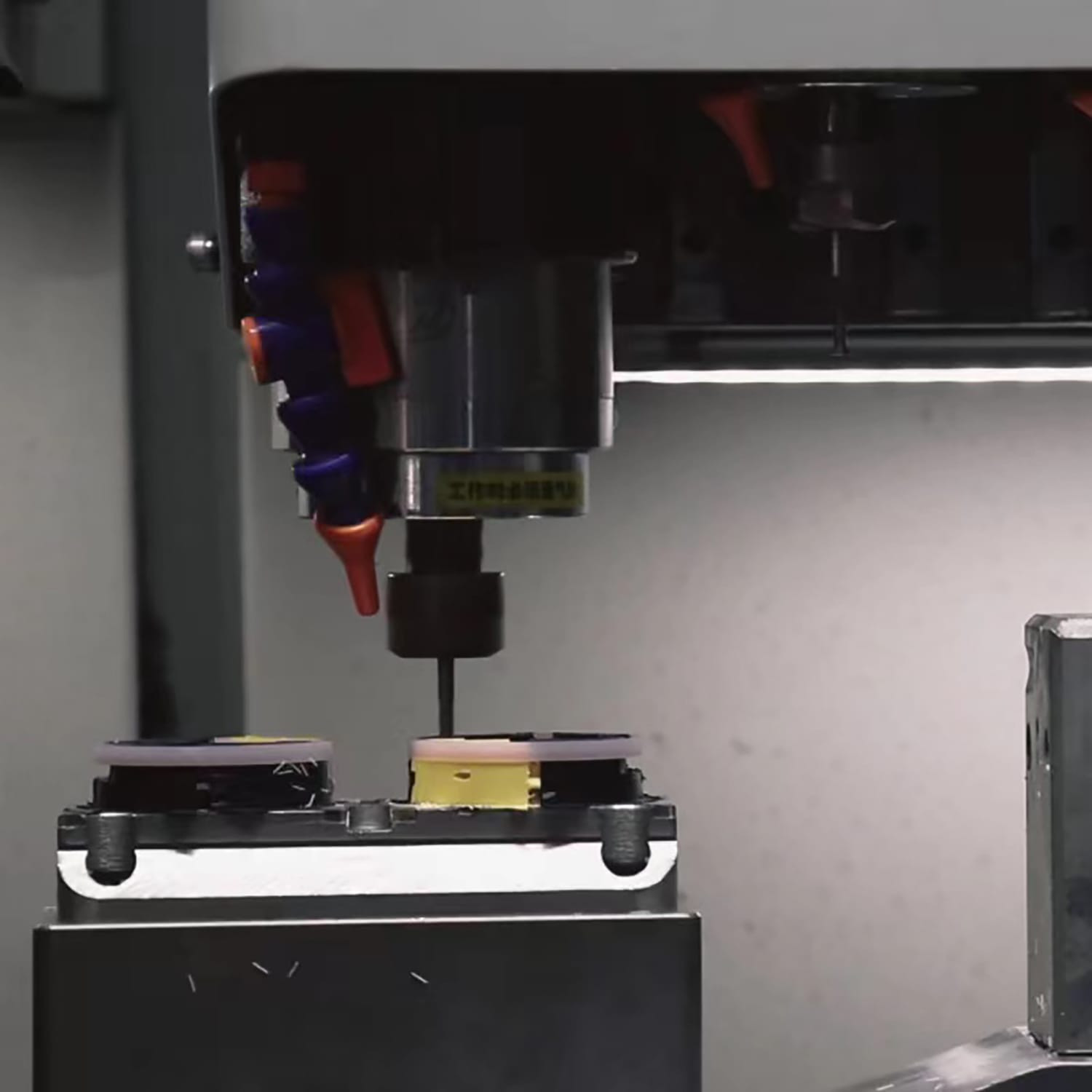

- CNC cutting & injection molding shape the frames.

- Hand-finishing & polishing enhance the quality.

- Automated assembly lines ensure precision and consistency.

3.5 Quality Control & Certifications

- Every batch undergoes strict quality control to meet ISO, CE, and FDA standards.

- We inspect for lens clarity, frame durability, and hinge strength before shipping.

4. Customization Options at Joysee Eyewear

At Joysee Eyewear, we offer extensive customization, ensuring your brand stands out.

4.1 Frame Styles & Materials

- Classic & trendy designs tailored to different market needs.

- Eco-friendly options (biodegradable acetate, recycled plastics).

4.2 Lens Technologies & Coatings

- Polarized lenses – Reduce glare & enhance clarity.

- Photochromic lenses – Adjust tint based on sunlight exposure.

- Anti-blue light lenses – Ideal for digital device users.

4.3 Branding & Logo Printing

- Custom laser engraving, silk screen printing, and metal inlays for logos.

- Fully personalized packaging & case designs available.

5. Why Choose Joysee Eyewear as Your Custom Sunglasses Manufacturer?

5.1 10+ Years of Manufacturing Expertise

- We have supplied over 500 global brands with premium sunglasses.

5.2 State-of-the-Art Production Facilities

- Advanced automated machinery & skilled handcrafting techniques.

5.3 Eco-Friendly & Sustainable Manufacturing

- We prioritize sustainable materials and low-waste production processes.

5.4 Global Shipping & Fast Lead Times

- Orders are delivered worldwide within 30-45 days.

6. Case Studies: Success Stories from Our Clients

📌 Case Study 1: Luxury Fashion Brand

A high-end fashion label partnered with Joysee Eyewear to create a limited-edition sunglasses collection. The line sold out in 3 weeks, thanks to premium design & fast production turnaround.

📌 Case Study 2: Sustainable Startup

A startup focused on eco-friendly eyewear collaborated with us to produce recycled acetate sunglasses. Their sales grew by 250% within the first year.

📌 Case Study 3: Corporate Promotional Campaign

A global corporation ordered custom-branded sunglasses for a marketing campaign. The campaign saw a 50% increase in customer engagement.

7. Future Trends in the Custom Sunglasses Industry

- Smart Sunglasses with built-in AR & Bluetooth.

- Biodegradable Materials for eco-conscious brands.

- AI-Driven Customization for on-demand production.

At Joysee Eyewear, we stay ahead of these trends, ensuring our clients receive the most innovative, high-quality products.

8. Conclusion: How to Start Your Custom Sunglasses Project with Joysee Eyewear

Partnering with a reliable custom sunglasses manufacturer like Joysee Eyewear guarantees premium quality, full customization, and fast delivery.

📞 Contact Us Today to start your custom sunglasses project and elevate your brand!

- Allen Lin - Joysee Eyewear

- (+86) 13456050627

- Info@Joysee-optical.com

- 3dr Fl B3 81 ZhongHui Rd Wenzhou Chiny

- Dostępne od poniedziałku do niedzieli od 08:00 do 22:00